vickers hardness test for brass|vickers hardness testing machine diagram : dealer The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 . r/GatasBR. • 8 mo. ago. LetSubstantial9993. NSFW. Isadora Vale | @isadoravale_ TIKTOKER 🎵. 753. Sort by: LetSubstantial9993. MOD • 8 mo. ago • Stickied comment. .

{plog:ftitle_list}

Resultado da The latest tweets from @AquariumGays

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .

Standard industry hardness testing methods, including Rockwell, Brinell, or Vickers, will suffice for brass. However, the testing method often requires a hardness testing .The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.How Does a Vickers Hardness Tester Work? 1. Preparation. 2. Application of Load. 3. Indentation. 4. Measurement. 5. Calculation. 6. Determination of Hardness. 7. Reporting. Advantages of Vickers Hardness Tester. 1. Broad .The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. .

Vickers hardness test is also known as the diamond pyramid hardness test which employs a diamond pyramid indenter and variable loads ranging from 1 to 120 kg. The Vickers hardness .The Vickers hardness test at a glance: Ideal for micro hardness testing. Can be used for case hardness depth measurement, Jominy testing and hardness testing of welds. Standards: ASTM E384, ISO 6507 and JIS Z 2244. See our .

When you require precise measurements for materials with high hardness or thin coatings – the Vickers hardness test is suitable. When needing to perform hardness testing on-site or non-destructively – the Leeb hardness test .The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Vickers method is based on an optical measurement system.

The Vickers hardness test is based on the principle of indentation hardness, where a diamond indenter with a square-based pyramid shape is pressed into the surface of the material under a specified load.

centered-cubic structure. The brass alloy used in this teaching module is an easily available material that is ductile enough to be rolled easily. Hardness tests can be done using a number of methods—this module uses Vickers Hardness ("HV"), but other tests would give similar results. All hardness testing methods are completed using the same15.2.3.2 Hardness Test. A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N with a dwelling time of 12 s. Hardness measurements were performed on the cross-section surfaces of the rolled strips along the .Vickers Hardness Testing. Microhardness testing of metals, ceramics, and composites is useful for a variety of applications for which 'macro' hardness measurements are unsuitable: testing very thin materials like foils, measuring .

Numerical-hydrodynamic analysis, vickers hardness, and tensile test of cast-brass alloy for boat propellers Computational Fluid Dynamics (CFD) has been applied to simulate boat propellers. The material for boat propellers generally uses a brass alloy .Brass: Brass (bar) Cz121 | C360 | 2.0401 CuZn36Pb3: 90 to 160--Brass: Brass (billet) Cz112 | C464 | 2.0321 | CuZn36Sn1: 80 to 135--Carbon Steel: . The Vickers hardness test utilises a diamond pyramid-shaped indenter to create a small impression on the material's surface. Taking into consideration the weight of the load, the size of the .This Vickers hardness number calculator uses the size of indentation to return the hardness of the material. There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and Vickers hardness test.. The Vickers hardness scale, named after the company where it was developed in 1921, is the focus of this article. Hardness test and the tensile strength of cast brass alloy from boat propellers have been experimented, as well as macro and micrographic observations of fracture surfaces due to tensile tests

among Brinell hardness, Vickers hardness, Rockwell hardness, and Rockwell superficial hardness of cartridge brass. 1.5 Conversion Table 5 presents data on the relationshipSafety. Our Vickers hardness testers meet all common safety requirements, including limit switches for limitation of the travel distance and collision warning features. During development of our Vickers hardness tester, ZwickRoell particularly emphasizes on the safety of the operator and machine. Furthermore, a user-friendly Vickers hardness tester is characterized by a .1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness testing machines (Part B), and the calibration of standardized hardness test blocks (Part C). Two general classes of standard tests are recognized: The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness (1) The geometrical shape of the indentation is always similar, while the load can be varied. . Brass Alloy Hardness and Strength: Conversion Chart

To determine the indentation hardness of mild steel, brass, aluminium etc. using Vickers hardness testing machine. . Vickers hardness testing machine. the time. The load is applied for a period of 10 to 15 seconds. Indentation diagonal length. Indentation diagonal length. hv=0.8191F/d 2: d1: d2: Trial: Specimen: Load Applied ( kg ) .Objective: The Vickers hardness test mainly serves to measure the hardness of materials, its physical durability. Hardness is defined as a material's “resistance to deformation” (#1) and it can vary depending on the material. . 360 Half Hard Brass Alloy. 660 660 832 847 678 702 728 105. 110 Copper 833 836 834 840 836 80 Zirconia (ZrO2 .

Download scientific diagram | Vickers hardness test: data on brass. from publication: Indentation modulus at the macro-scale level measured by Brinell and Vickers indenters by using the primary . HV, HB, HRC Hardness Comparison Chart. Hardness testing is the simplest and most straightforward method among mechanical property tests. In order to replace certain mechanical property tests with hardness tests, a .维氏硬度测量仪. 维氏硬度试验(英語: Vickers hardness test ),是压入硬度试验之一种,其测量值用HV表示。. 维氏硬度试验最初于20世纪20年代初被提出,比起其他硬度试验其优点有:硬度值与压头大小、负荷值无关;无需根据材料软硬变换压头;正方形的压痕轮廓边缘清晰,便于测 .A variety of hardness-testing methods are available, including the Vickers, Brinell, Rockwell, Meyer and Leeb tests. Although it is impossible in many cases to give an exact conversion, it is possible to give an approximate material-specific comparison table for steels .

For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the Vickers hardness values are comparable to a certain degree with the Brinell hardness values (applies to approx. 400 HBW or 400 HV). The .

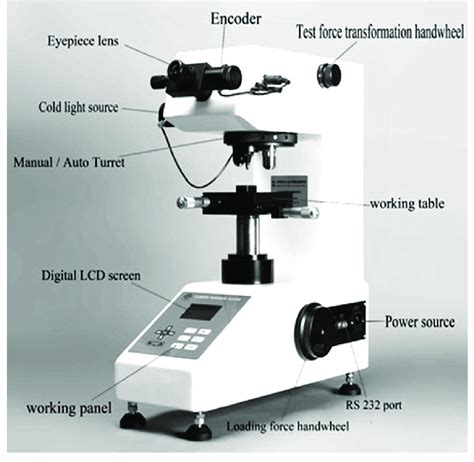

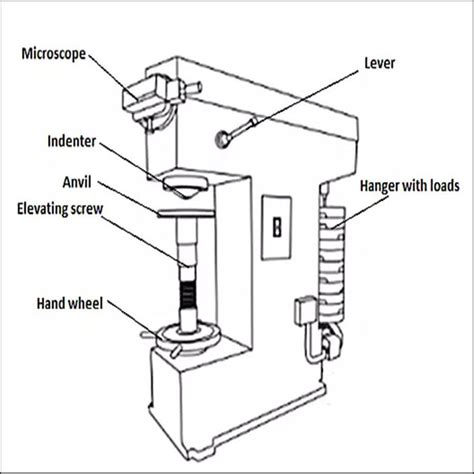

vickers hardness testing machine diagram

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .Brass. Approximate Hardness Conversion No.s for Cartridge Brass (70&perc Cu 30% Zn Alloy) Vicker’s Hardness Number (HV) Rockwell Hardness Number B Scale, 100 Kgf (HRB): Rockwell Hardness Number F Scale, 600 Kgf (HRF): Rockwell Superficial Hardness No. 15T Scale, 15 Kgf (15T) Rockwell Superficial Hardness No. 30T Scale, 30 Kgf (30T) Rockwell Superficial .

Video ini menjelaskan cara melakukan pengujian kekerasan dengan metode vickers. Pengujian vickers merupakan salah satu dari banyak metode uji kekerasan. peng.The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the indentation left in the surface The Vickers hardness test is based on the principle of indentation hardness, where a diamond indenter with a square-based pyramid shape is pressed into the surface of the material under a specified load. The diagonals of the resulting indentation are measured using a microscope, and the Vickers hardness value is calculated using a formula that .

Numerical-hydrodynamic analysis, vickers hardness, and tensile test of cast-brass alloy for boat propellers Computational Fluid Dynamics (CFD) has been applied to simulate boat propellers. The material for boat propellers generally uses a brass alloy .

3. Vickers Hardness (HV) Vickers hardness is determined by pressing a diamond square cone with a 136° top angle and a load of up to 120kg into the material’s surface. The Vickers hardness value (HV) is calculated by dividing the load by the surface area of the indentation pit, expressed in kgf/mm². 4. Leeb Hardness (HLD)Brass is is the generic term for a range of copper-zinc alloys. Brass can be alloyed with zinc in different proportions, which results in a material of varying mechanical, corrosion and thermal properties. . The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell . Brass Alloy Hardness and Strength: Conversion Chart . Vickers: Rockwell: Surface Rockwell: Brass: HB30D 2: d 10,2d 5,4d 2.5 /mm: HV: HRB: HRF: HR15T: HR30T: . During a test of the cylinder head tightness of a gas engine, water leaked, and after disassembling and inspecting the engine, cracks were found in the spark plug bushing. .

node js 100 connection test package

Resultado da 18 horas atrás · A pair of photos released by Beaumont RCMP of a suspect wanted in connection with a fatal hit-and-run involving a U-Haul truck that killed a 45-year-old Fort Saskatchewan woman. Photo by Supplied .

vickers hardness test for brass|vickers hardness testing machine diagram